Knauss legislative fellowships in Congress help build careers — and they're fun and educational. See our video and fact sheet for details.

R/E-24e

Tool Development to Characterize Flow Regime in Oyster Aquaculture Systems

Principal Investigator:

Matthew GrayStart/End Year:

2019 - 2020Institution:

University of Maryland Center for Environmental ScienceCo-Principal Investigator:

Brendan Campbell, University of Maryland Center for Environmental Science, Horn Point LaboratoryTopic(s):

Strategic focus area:

Sustainable fisheries and aquacultureDescription:

The aquaculture industry in Maryland is far from optimized partly due to the lack of knowledge relating oyster growth and morphology to the physical environment (flow and jostling). For sessile suspension feeders, such as oysters, water flow is critical to optimize under culture conditions as it regulates food delivery and waste export. Additionally, jostling may inhibit feeding activity and influence shell shape, the latter of which may influence product marketability. It is also unknown how different off-bottom cage types affect the flow regime. This lack of understanding is not unique to Chesapeake Bay waters but is a concern for oyster farmers globally. The tools required to make these assessments are also not readily available to researchers and stakeholders due to technical limitations and high cost. To fill this knowledge gap, our main objectives are to: 1) develop and validate simple and inexpensive tools (specifically clod cards, ammonia peepers, and accelerometers) that have the potential to monitor fine-scale, interior physical conditions of off-bottom cages 2) draw relationships between oyster growth and quality with a changing physical environment 3) test tools among varying gear types available at the Horn Point Laboratory Demonstration Farm (HPLDF) to examine differences in gear performance 4) provide tools and education to local stakeholders on the importance of considering flow when planning farm operations. Additionally, these tools may be used to better understand how biofouling communities persist and influence the movement of water through gear. Collectively, this applied research project aims to develop tools and collect information to provide deeper understanding of gear performance, which is fundamental for farm optimization and profitability.

Impact/Outcome:

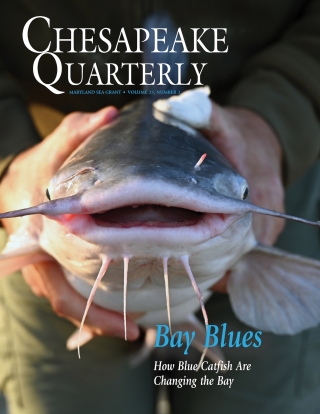

Title: Going With the Flow: Helping Oyster Growers Maximize Their Product by Monitoring Water Flow and Movement in Aquaculture Gear

Recap: A Maryland Sea Grant fellow is developing inexpensive tools to help oyster growers measure the movement of water in their cages and gear, providing data that will help them optimize oyster growth and quality.Relevance:Growing the oyster aquaculture industry in Maryland is a high priority. Wild populations of the Eastern oyster (Crassostrea virginica) have diminished due to disease, over harvesting, habitat loss, and poor water quality. Oyster aquaculture can introduce more of the filter-feeding bivalves into the Chesapeake Bay and Coastal Bays. Oyster farms can improve water quality and provide watermen a viable economic option to the dwindling wild harvest. As of December 2020, there were 486 active shellfish leases in Maryland’s portion of the Chesapeake Bay and Coastal Bays, comprising 7,539 acres.Research has shown that the rate and character of water movement will affect an oyster’s shape, growth rate, and meat quality. Scientists still need to better understand how water flow from current, tides, and wave motion in oyster gear—bags and cages—impacts oyster growth. Finding affordable, efficient methods for oyster farmers to monitor water flow and movement can help them optimize production and, in turn, help grow oyster aquaculture.

Response: For the past two years, Maryland Sea Grant Fellow and PhD student Brendan Campbell has been developing water flow and movement tools and testing them at the University of Maryland Center for Environmental Science’s Horn Point Laboratory. The clod card—a small ball made of plaster of Paris and distilled water—is suspended in oyster gear. As water moves across it, the card dissolves at a linear rate, providing data on the amount of water moving through the gear. Attaching an off-the-shelf, $85 accelerometer into an empty oyster shell and installing it in the gear also provides data on how much oysters are jostled or moved by water flow. COVID-19 restrictions prevented Campbell from carrying out a full-scale assessment of these tools on a working oyster farm in 2020; however, he plans to conduct that research in 2021 in a subset of 20-30 cages on a commercial farm of approximately 500 cages near Solomons, Maryland.

Results: Once these tools are field tested and made available, they will help farmers continually monitor water movement in their gear at low cost, and change their grow-out depth or location accordingly. Campbell is also working to quantify how various water movement rates will produce certain types of oyster growth. He is also seeking a way to Bluetooth-enable the accelerometers, so that farmers can access the data remotely.